Material and color appearance of onion mesh belt dryer machine:

Material:

The mesh belt of the onion mesh belt dryer machine in contact with the material adopts food grade 304 stainless steel, and the main frame defaults to galvanized square tubes (which can be upgraded to 304 stainless steel or other higher grade food grade materials according to user needs). The shell plate of the onion dryer adopts Q235 (which can be upgraded to 304 stainless steel or other types of stainless steel according to actual needs)

Color and appearance:

Using Q235 steel plate as the shell, the user can specify the appearance color (default appearance is silver-white). If 304 grade and above grade stainless steel is used as the shell, the default is the original color of the stainless steel (stainless steel plate can use brushed surface or embossed surface)

Onion mesh belt drying production line generally includes onion peeler, onion blanching machine, onion slicer or onion shredder, onion dryer and onion conveyor connecting each equipment. Each equipment works together to realize the automated operation of the onion drying production line.

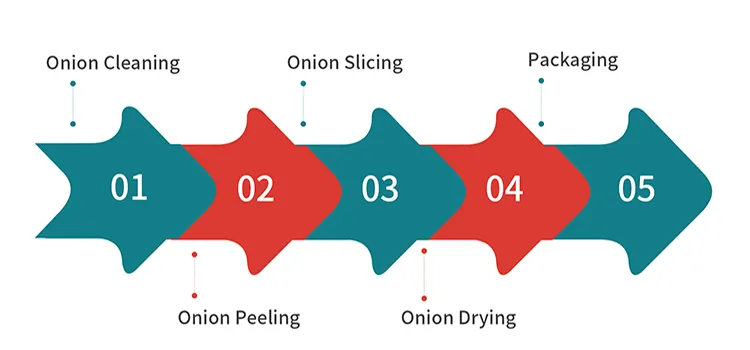

Commercial mesh belt onion dryer machine is a special equipment for drying onions, which has the characteristics of energy saving, environmental protection, high efficiency and easy operation. The process of onion drying and dehydration generally includes onion cleaning, onion peeling, onion slicing or shredding, onion drying, and finished product packaging.

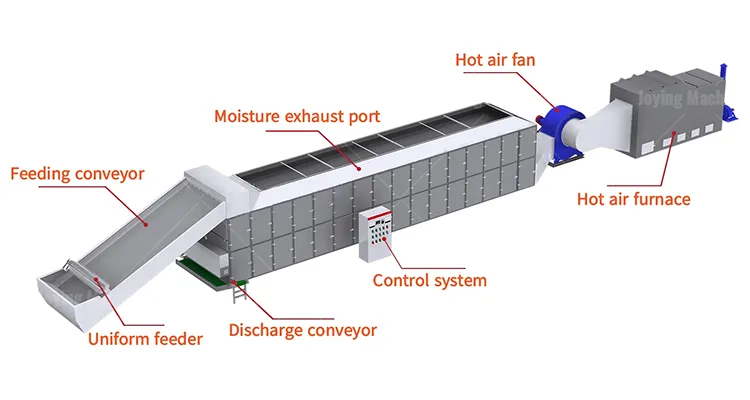

The mesh belt onion dryer machine usually consists of onion feeding system, drying box, conveying mesh belt, hot air generation system, dehumidification system and control system. Among them, the feeding system is also equipped with an even material system to ensure that the materials are evenly fed into the dryer. The drying box is equipped with multiple layers of conveying mesh belts, and the onions are transported back and forth layer by layer from the top layer of the mesh belt to the bottom layer of the mesh belt, so that the onions are in long-term contact with the hot air evenly in the drying box, ultimately achieving the purpose of hot air drying. The heating system has multiple energy sources to choose from, such as steam energy, electricity, natural gas, liquefied gas, etc. The dehumidification system is responsible for timely discharging the water vapor generated during onion drying and accelerating the hot air velocity, improving the drying efficiency and drying effect.

After drying and dehydration, onions are widely used and can be directly sold for cooking. They can also be used as raw materials to make other onion foods through deep processing of onions, such as onion powder and onion sauce. Onion mixed seasonings, etc.

Users can choose different models of onion mesh belt dryer machine according to their own needs, drying scale, investment amount and other factors to meet their own production needs. In addition, users need to focus on energy type and energy cost performance. Different energy types have a very significant impact on drying efficiency, drying effect and drying cost.

In conclusion, the commercial mesh belt onion dryer is an important equipment in onion processing, which is of great significance for improving production efficiency and product quality. When purchasing, it is necessary to consider various factors comprehensively and choose suitable equipment to meet production needs and achieve maximum economic benefits.