Advantages and applications

Freeze dryers are widely used in the food dehydration industry. Almost any imaginable fruits, vegetables, meats and seafood can be dehydrated with freeze dryers.

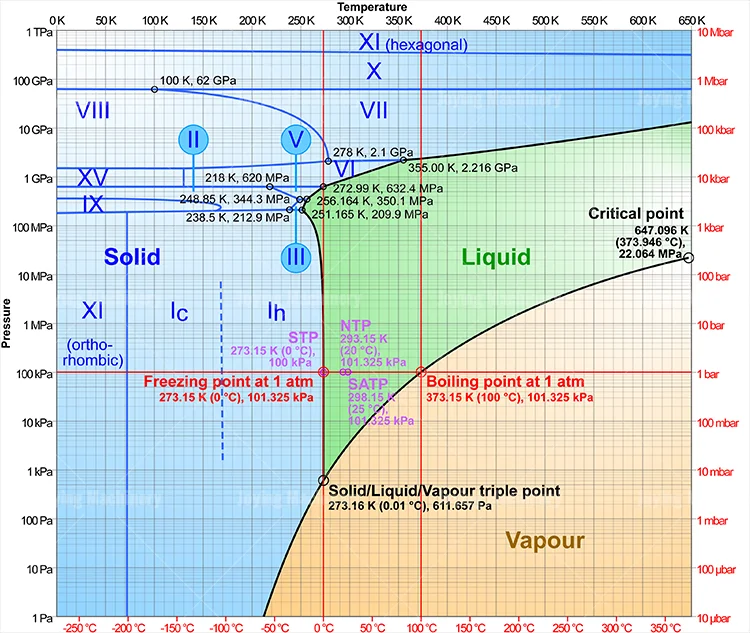

Freeze-drying technology utilizes the mutual conversion principle of water's gaseous, liquid and solid states. In a low-temperature vacuum environment, ice is directly vaporized to achieve the purpose of dehydration. Using freeze-drying technology to dehydrate food has the following advantages:

- It can be stored for a long time and can retain the original color, fragrance and nutrients of food to the maximum extent. It is the best food dehydration method at the moment.

- Freeze-drying is carried out in a low-temperature environment, so heat-sensitive substances such as proteins and microorganisms will not change or lose biological activity.

- The freeze dryer dehydrates food without affecting the shape and volume of the food, and maintains the original structure and shape of the food.

- The freeze-dried food has a sponge-like interior and can return to its original appearance when exposed to water.

- Since the entire dehydration process is carried out under vacuum, some easily oxidized foods avoid oxidation problems.

- The dehydration effect is good and can remove more than 95% of the water in food, greatly extending the shelf life of food.

- Since the frozen water exists in solid form, after direct gasification, the nutrients originally dissolved in the water are evenly retained in the food.

- The freeze-dried food has a crispy texture and is more popular among the public.

Based on the above advantages, freeze dryers are widely used. Freeze-dried fruits, vegetable packages, meat products and seafood are very common in large supermarkets. In addition, freeze dryers are often used in the medical industry and bioengineering industry.