According to the drying principle, there are the following types of dehydrator for chili peppers:

Material:

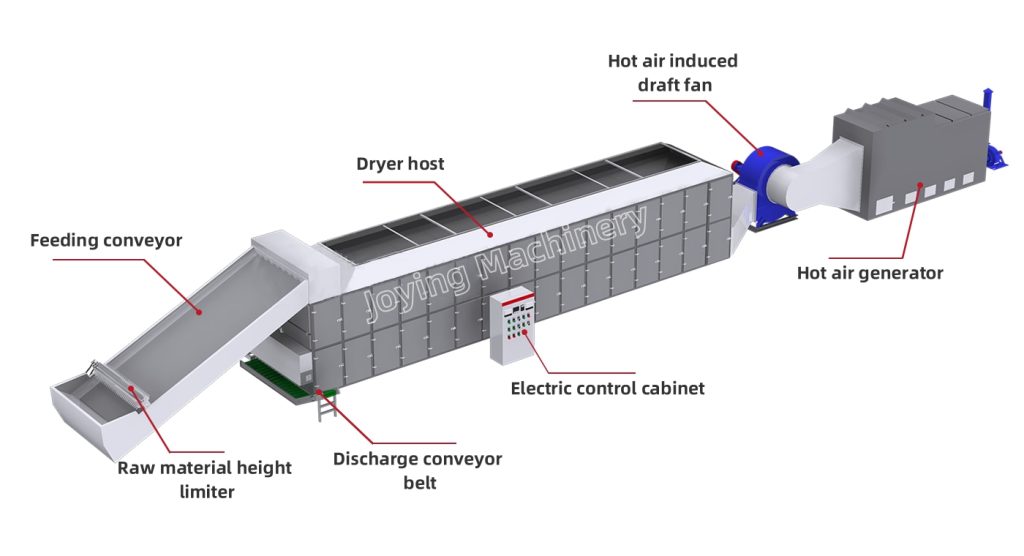

The entire chilli freeze-drying machine is made of food-grade 304 stainless steel. The tray of the pepper heat pump drying room is made of 304 stainless steel mesh. The entire mesh belt of the pepper belt dryer is made of 304 stainless steel mesh.

The selection of supporting equipment for pepper dehydration machines is mainly determined based on the output and degree of deep processing of peppers. Normally, for users who do not have large requirements for pepper dehydration output, they only need to choose a pepper drying room. If you want greater output, you need to choose a mesh belt pepper dehydrator. If the user wants to further process, such as turning dehydrated peppers into chili powder or chili sauce, they will need equipment such as a chili grinder and a chili blender. You can also communicate with us and get confirmation.

Many users know little about pepper dehydrators and do not know how to buy a useful pepper dehydrator when purchasing. Generally speaking, the best dehydrator for chili peppers generally has the following characteristics:

1.The temperature and drying time can be adjusted freely.

A useful dehydrator for chili peppers must allow the user to freely adjust the drying temperature and drying time during the pepper dehydration process. Users often need to dehydrate more than one type of pepper, and the water content and size of the peppers are also different. At this time, the pepper dehydrator can adjust the temperature and drying time to ensure that different varieties of peppers can meet the user's moisture, color and other requirements after dehydration.

2.It must be able to dry evenly.

The drying structure of the pepper dehydrator purchased by many users is unreasonable, resulting in the color of the dried peppers being dark or light, some have been dried, and some still have a high moisture content. The main reason is that the structure of the pepper dryer is unreasonable, resulting in a large deviation in the amount of hot air blowing on the peppers during drying, which is not stable enough. Therefore, the hot air blown out by a good dehydrator for chili peppers has a similar temperature and the hot air can be output evenly.

3.The capacity should be moderate.

When users purchase a pepper dehydrator, they should choose the appropriate pepper dehydrator model based on the amount of peppers that need to be dehydrated. Doing so can not only ensure that the output of dried chili peppers meets user needs. At the same time, unnecessary waste of energy is avoided and drying costs are minimized.

4.Brand reputation and after-sales service.

A professional pepper dehydrator manufacturing factory can provide users with more and more comprehensive guarantees and after-sales services. It allows users to only focus on the sales and management of peppers when running a dehydrated pepper business, reducing production costs and creating more value for users.