When it comes to industrial drying, precision is everything. A belt dryer’s control system is the brain behind the operation, ensuring that every batch of fruits, vegetables, or herbs is dried to perfection. As someone who has worked with these machines for years, I can tell you that the control system is what sets a high-quality belt dryer apart from the rest. But how does it actually work? Let’s break it down.

The control system in a belt dryer manages key parameters like temperature, humidity, and belt speed to ensure consistent and efficient drying. It’s designed to automate the process, reduce human error, and deliver high-quality results every time.

If you’re curious about how this system operates and why it’s so important for achieving optimal drying results, keep reading. I’ll explain the key components and functions of the control system in a way that’s easy to understand.

What Is the Role of the Control System in a Belt Dryer?

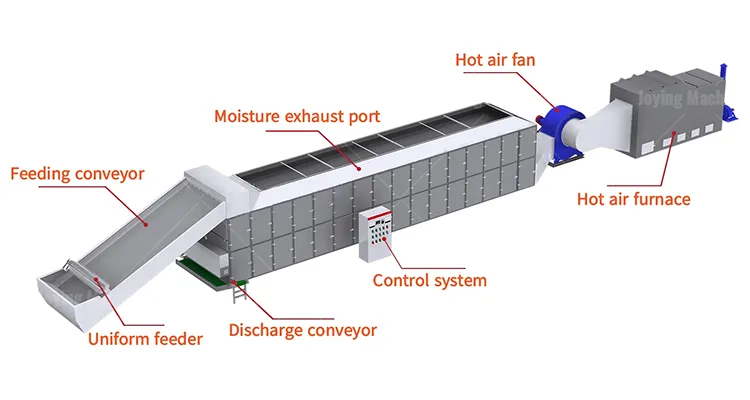

The control system is the heart of a belt dryer. It oversees every aspect of the drying process, from the temperature inside the drying chamber to the speed of the conveyor belts. Without it, achieving consistent results would be nearly impossible.

The control system ensures that the drying conditions remain stable throughout the entire process. This is crucial for maintaining the quality, taste, and nutritional value of the dried products.

Think of it like a conductor in an orchestra. It coordinates all the moving parts to create a harmonious result. Whether you’re drying delicate herbs or robust root vegetables, the control system ensures that everything runs smoothly.

Key Components of the Control System

Temperature Control

One of the most critical functions of the control system is regulating the temperature inside the drying chamber. Different products require different drying temperatures, and the control system allows you to set and maintain the ideal level.

Temperature control is essential for preventing over-drying or under-drying. Too much heat can damage the product, while too little can leave it moist and prone to spoilage.

The system uses sensors to monitor the temperature in real-time and adjusts the heating elements as needed. This ensures that the drying environment remains consistent, even as external conditions change.

Humidity Control

Humidity plays a significant role in the drying process. If the air inside the chamber is too humid, the products won’t dry properly. On the other hand, if it’s too dry, the products may lose too much moisture too quickly.

The control system manages humidity levels by adjusting the airflow and ventilation. This helps maintain the perfect balance for efficient drying.

Some advanced belt dryers even come with dehumidifiers or humidifiers integrated into the system. These features allow for even greater precision, especially when working with sensitive materials like herbs or flowers.

Belt Speed Control

The speed at which the conveyor belts move is another factor that affects the drying process. Faster speeds mean shorter drying times, but they can also lead to uneven results if not managed properly.

The control system allows you to adjust the belt speed to match the specific needs of your product. This ensures that each batch is dried evenly and thoroughly.

For example, delicate herbs might require a slower speed to prevent damage, while sturdier vegetables can handle a faster pace. The control system makes it easy to customize the process for different materials.

Automation and Monitoring

One of the biggest advantages of a modern belt dryer is its automation. The control system can be programmed to handle the entire drying process, from start to finish, with minimal human intervention.

Automation not only saves time and labor but also reduces the risk of human error. This is especially important for businesses that need to meet strict quality standards.

The system also includes monitoring features that allow you to track the progress of each batch in real-time. If any issues arise, such as a sudden drop in temperature or a malfunctioning belt, the system will alert you immediately.

Why Is the Control System So Important?

Consistency and Quality

In the food processing industry, consistency is key. Customers expect the same high-quality product every time, and the control system ensures that this standard is met.

By maintaining precise control over the drying conditions, the system guarantees that each batch is dried to perfection. This consistency is what builds trust and loyalty with customers.

Efficiency and Cost Savings

A well-designed control system can significantly improve the efficiency of your drying process. By automating tasks and optimizing conditions, it reduces the time and energy required to dry each batch.

This not only lowers operating costs but also increases your overall productivity. For businesses looking to scale up, these savings can make a big difference.

Flexibility and Customization

Every product is different, and the control system allows you to tailor the drying process to meet your specific needs. Whether you’re working with fruits, vegetables, or herbs, you can adjust the settings to achieve the best results.

This flexibility is especially valuable for businesses that handle a wide range of products. It ensures that you can adapt to changing demands without compromising on quality.

Conclusion

The control system in a belt dryer is what makes it such a powerful tool for industrial drying. By managing temperature, humidity, and belt speed, it ensures consistent, high-quality results every time. Whether you’re drying delicate herbs or robust vegetables, the control system provides the precision and flexibility you need to succeed. If you’re considering investing in a belt dryer, pay close attention to the control system—it’s the key to unlocking the full potential of this incredible machine.